What Is Masterbatch? The Real Reason Your Plastic Isn’t Fifty Shades of Grey

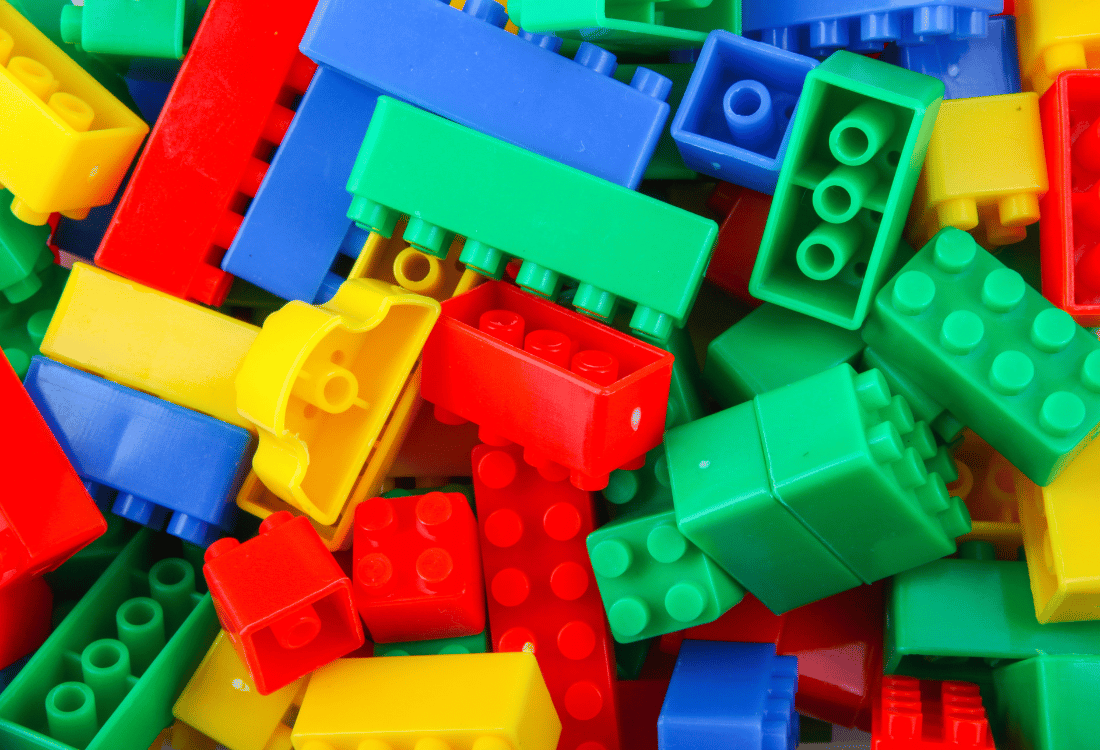

While it’s perfectly possible to apply a paint finish to plastic parts as you would with metal or wooden components, a big advantage of plastics is the ability to skip this step by colouring them during the manufacturing process.

Most plastics in their natural form are a neutral colour, often with some level of transparency, which makes them very easy to colour. In fact, a lot of development effort has gone into making the natural colour of plastics as neutral and as clear as possible, and If you were to look at a ‘natural’ ABS from 30 years ago, it would look a lot ‘milkier’ than a modern grade.

Although it is possible to add colour during the polymerisation process, in practice the colour is typically added in a secondary compounding operation, often alongside other additives, or directly in the barrel of the injection moulding machine.

So What is Masterbatch Exactly?

What is masterbatch in simple terms? Think of it as a concentrated colour that transforms your entire production run. A masterbatch is a concentrated mixture of pigments, or other additives, encapsulated in a carrier resin. This concentrated material is then diluted into the natural polymer during processing.

To understand this better, imagine the custom paint tinting process at your local DIY shop. When you want a specific shade of blue for your living room, the staff don't mix individual pigments from scratch. Instead, they take a base of white paint and add precise drops of concentrated blue colourant. Those few drops of concentrated colour transform the entire tin of paint to your exact specification. That's essentially what happens with masterbatch - a small amount of concentrated colour pellets transforms your entire batch of natural plastic.

Before the development of masterbatches, achieving consistent and accurate colour required the careful preparation of liquid or powdered dye mixes, followed by precise blending with the natural polymer before moulding. Maintaining consistent colour across production runs, and managing dust and contamination from the dyes, presented significant challenges on the factory floor.

The Evolution to Modern Masterbatch Systems

The solution was to produce a large batch of pigment - a ‘master batch’ you might call it - that was encapsulated in a carrier resin such as LDPE and then repelletised. This allowed a small, easily measured quantity of the masterbatch to be added to the natural polymer in each production run, ensuring consistent colour across batches. Additionally, the controlled dispersion of the pigment led to fewer defects and improved overall product quality.

This innovation transformed how moulders work with colour. Instead of wrestling with powdered dyes, you could simply order the exact shade you needed from your masterbatch manufacturer and add the precise amount to each batch. The masterbatch meaning in practical terms became synonymous with consistent, reliable colouring that eliminated the guesswork and contamination risks of earlier methods.

Why This Matters for Your Production Line

Over time, the step of 'adding a small portion of the master batch' evolved into the shorthand of 'add masterbatch' - a testament to how integral this process became to modern plastic manufacturing.

Today, when you're sourcing colours for a new project, you're not just buying pigment - you're buying consistency, quality control, and production efficiency all rolled into one convenient pellet. That's the real genius behind masterbatch technology, and exactly what is masterbatch's biggest advantage over traditional colouring methods.

We work directly with leading masterbatch manufacturer partners to ensure you get exactly this level of reliability. Our relationships with each masterbatch manufacturer allow us to offer competitive pricing and technical support, while our masterbatch manufacturer partnerships enable us to provide the exact specifications your project demands. Best of all, we handle masterbatch manufacturer relationships so you don't have to deal with multiple suppliers and minimum order quantities.

How Naphtha Plastics Can Help With Your Masterbatch And Polymer Needs

Now that you understand what masterbatch is and its role in modern manufacturing, are you ready to source the right materials for your next project? At Naphtha Plastics, we've been supporting injection moulders and manufacturers for over 40 years with high-quality polymers and masterbatch solutions. Our experienced team can help you with:

- Masterbatch Supply: We stock a comprehensive range of colour and additive masterbatches from leading suppliers, ensuring consistent quality for your production runs.

- Prime Polymers: From commodity plastics to engineering grades, we supply the right base materials to work perfectly with your chosen masterbatch.

- Technical Support: With decades of industry experience, we can advise on material selection and help troubleshoot any processing challenges.

- Flexible Ordering: Whether you need a 5kg trial bag of masterbatch or a full truckload of polymer, we're here to support projects of any size.

- Fast Delivery: Orders placed before 2pm can be delivered next-day throughout Great Britain, keeping your production schedules on track.

Contact Us

Ready to talk about your masterbatch and polymer needs? Whether you’re looking to perfect colour, improve performance, or solve tricky plastic issues, our team can help. Contact us today to discover how the right masterbatch can transform your plastics and keep your projects looking exactly as intended.

Latest articles

Subscribe to our blog

You May Also Like

These Related Stories

What Is Plastic Regrind? Giving Old Plastics a Second Spin

What Is Thermoplastic Elastomer? The Shape-Shifter of Materials